does the long time in autoclave affect the dextruse|autoclave temperature chart : broker Autoclaving is an efficient and effective sterilization method for labs, breweries, dentist offices, tattoo parlors, and other places that consistently need sterilized items. However, while . SOP for Validation of Autoclave Standard operating procedure to validate the steam sterilizer using biological indicators having spores of Bacillus stearothermophilus ATCC .This operation manual consists of the following sections covering the information required for proper operation of the Autoclave HVA-85/110: Chapter 1. What is the Autoclave HVA-85/110? .

{plog:ftitle_list}

Standard operating procedure to validate autoclave with biological indicator for sterilization efficiency.

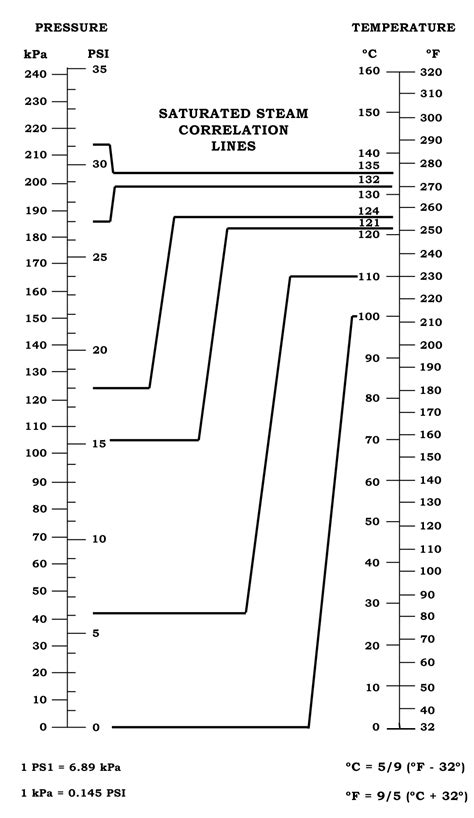

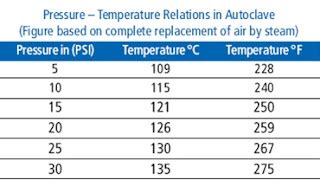

A practical approach for studying the breakdown of dextrose under simulated sterilization conditions has been developed using a special laboratory instrument. The instrument allows for control of pressure, temperature, and time of heating of the solutions under .The autoclaving time of 121 °C and 15 min resulted in the lowest levels of 3-DG/3-DGal and 5-HMF, but in the highest levels of GO and 2-KDG. The proposed LC-MS/MS method is rapid . Temperature plays a pivotal role in autoclave sterilization, as it directly influences the efficiency and effectiveness of the process. The optimal temperature for sterilization . Sterilising glucose solutions by heat promotes the generation of a large number of glucose degradation products (GDPs). It has been shown that high levels of GDPs may result .

Autoclaving is an efficient and effective sterilization method for labs, breweries, dentist offices, tattoo parlors, and other places that consistently need sterilized items. However, while .

Autoclaving is a type of sterilization that uses high-pressure cooking and is usually operated at 5–15 psi and 112°C–127°C for 10–50 min. When it is applied to cereal or plant-based foods, .By creating a vacuum in the chamber, we are able to lower the boiling point of water, in doing so and considering the load is hot following the sterilization phase, we are able to create a .

For the standard autoclaving process at 121°C, a sterility assurance level of 10 −6 is typically achieved; at the same time glucose degradation products (GDPs) may be formed . The minimum sterilization time, however, can vary significantly due to how many flasks you are sterilizing, how you place the flasks in the autoclave, and what type of liquid you .

autoclave temperature chart

The argument could be made that glucose concentrations should be taken after autoclaving, however the variability of autoclaving (i.e. consistency in loading volume, heating time and temperature .It is always good to autoclave once at 15lbs pressure at 121 0 C for 15-20 min,as it gives the best result. With my personal experience autoclaving PDA, twice has resulted either in no growth of . Autoclave users have the ability to customize sterilization cycles based on a number of parameters, including sterilization temperature. If the autoclave fails to reach the designated temperature in the time it takes to run the sterilization cycle, it will either abort the cycle or sound an alarm (i.e. low-temperature alarm.)

There can be a slight change in color, which may become more obvious if the bottle is left for too long after the pressure has come down (temp. remains near 100C); this does not seem to cause any .

Effect of thermal processing on the digestion of plant proteins. Kinza Mukhtar, . Rana Muhammad Aadil, in Processing Technologies and Food Protein Digestion, 2023. 16.5.4 Autoclaving. Autoclaving is a type of sterilization that uses high-pressure cooking and is usually operated at 5–15 psi and 112°C–127°C for 10–50 min. When it is applied to cereal or plant .

Long Cycle Times– The curing process in an autoclave may take hours and at times may even span for days depending on the number of parts to be processed. This can limit production speed and throughput. Maintenance and Operation- Autoclaves like other equipment need to be maintained so that they are always in good working condition. Also, an .The darkness of autoclaved YPD is due to Maillard reaction. See below for further details: The long sterilization time is due to the amount of time needed for the chamber to reach high atmospheric pressure required for sterilization and the amount of time it takes for the chamber to . Read on to discover more about how autoclave sterilization works, the role of essential elements, and much more. How Autoclave Sterilization Works. No matter the setting or application an autoclave is used for, most models rely on a combination of temperature, pressure, steam, and time to achieve sterilization.

Tighten autoclave doors thoroughly but not so much that you can’t get it back open; note that this only really applies to older autoclaves, most newer autoclaves will seal themselves. Select the appropriate program: minimum autoclave time should .Put 5 g of glucose in the conical flask and add 50 cm 3 of warm water. Swirl the flask to dissolve the glucose. Add 1 g of yeast to the solution and loosely plug the top of the flask with cotton wool. Wait while fermentation takes place. The time it takes will depend on the temperature, how well you mixed the reactants and the yeast’s freshness. Glucose and dextrose can do your brain and body good — as long as you don’t overdo it. Too much sugar of any kind raises your risk for diabetes and these health issues: Advertisement By harnessing the power of steam, pressure, and time, autoclaves can effectively eliminate microorganisms and spores, ensuring a safe and sterile environment. Adhering to proper procedures, understanding compatible and incompatible materials, and ensuring regular autoclave validation are essential for the successful and safe use of autoclaves. .

If a person does not address low blood sugar, and the effects become more extreme, the condition can lead to several short- and long-term effects. Short-term effects In severe cases of low blood .You can autoclave fructose and glucose for 20 min (solutions turn yellow indicating slight degradation), but you cannot autoclave, e.g., ribose (a pentose which disintegrates quickly at high . Air is rapidly removed from the load as with the prevacuum sterilizer, but air leaks do not affect this process because the steam in the sterilizing chamber is always above atmospheric pressure. Typical sterilization temperatures and times are 132°C to 135°C with 3 to 4 minutes exposure time for porous loads and instruments. 827, 837Autoclave the media. U sage instructions: Check the pressure and temperature gauges to ensure that the autoclave is not running before opening the door. Turn the wheel to open the door slowly, so that any steam inside does not blast out. Use the autoclave-specific cart to move the interior autoclave cart out on the rails using heat-protective .

Cost-Effectiveness: In the long run, autoclaves are cost-effective. They require minimal consumables other than water and energy, and their durability means they can be a one-time investment for many years. In comparison to other sterilization methods like ethylene oxide (EtO) sterilization, autoclaves are faster and do not require aeration .

As dextrose is a simple sugar that is absorbed quickly and raises blood sugar, it is usually not a healthy choice for the general population. If you have certain medical conditions (like chronic hypoglycemia) or are an athlete expending a lot of energy, dextrose can be beneficial for increasing energy and blood glucose levels rapidly.

The autoclave operator can calculate a lower cycle time for sterilizing the liquid based on the Fo (F Zero) empirical tables. If a normal sterilization holding time is set to 15 minutes, it may be reduced by seconds/minutes based on the Fo calculation. This will help prevent overcooking the liquid while still ensuring proper sterilization. When one autoclaves the media, under high temperature, the carbon dioxide gas within the solution is forced to be expelled out from the solution. This is based on Henry's law- Solubility of a gas . Insulin sensitivity is reduced by sleep deprivation and impacts glucose; The time of day a person sleeps impacts insulin and cortisol levels, both of which affect glucose; Increases in growth hormone accompany glucose increases during sleep; Oxidative stress and inflammation are increased by sleep deprivation and impact glucose

Note that many folks do not autoclave media containing dextrose — instead they autoclave everything else, then add filtered glucose solution (2% w/v in media; e.g., add 25 mL of 40% dextrose). For vacuum filter sterilization , attach the Nalgene filter assembly (VWR cat no. 28199-303 ) to a sterile 0.5 liter bottle, attach the hose to the . Autoclave the PDA at 15 lbs pressure (121°C) for 15 minutes to sterilize the medium and eliminate any potential contaminants.; After autoclaving, mix the PDA well to ensure homogeneity before dispensing it into sterile Petri dishes or tubes. If a specific pH of 3.5 is required for certain applications, the medium should be acidified using sterile 10% tartaric acid.

Figure 3. 1. Vessel. The vessel is the main body of the autoclave and consists of an inner chamber and an outer jacket. Laboratory and hospital autoclaves are constructed with “jacketed” chambers (see Figure 4), where the jacket is filled with steam, reducing the time that it takes to complete a sterilization cycle and reducing condensation within the chamber.Charles Chamberland (1851–1908) designed the modern autoclave in 1879 while working in the laboratory of Louis Pasteur. The autoclave is still considered the most effective method of sterilization (Figure 13.7). Outside laboratory and clinical settings, large industrial autoclaves called retort s allow for moist-heat sterilization on a large . Autoclaves use saturated steam under pressure of approximately 15 pounds per square inch to achieve a chamber temperature of at least 250°F (121°C) for a prescribed time—usually 30–60 minutes. In addition to proper temperature and time, prevention of entrapment of air is critical to achieving sterility. Material to be sterilized must come .

how to calibrate dd refractometer

how to calibrate digital refractometer

Autoclave treatment conditions to achieve sterility will vary in relation to the volume of material treated, volume of the autoclave, the contamination level, the moisture content, and other factors.

does the long time in autoclave affect the dextruse|autoclave temperature chart